AUTOMATIC LOADING SYSTEMS TO RETORTS OR PASTEURISERS

The Alserco team helps you increase your food thermal treatment productive capacity by optimising your equipment, your loading system and your process.

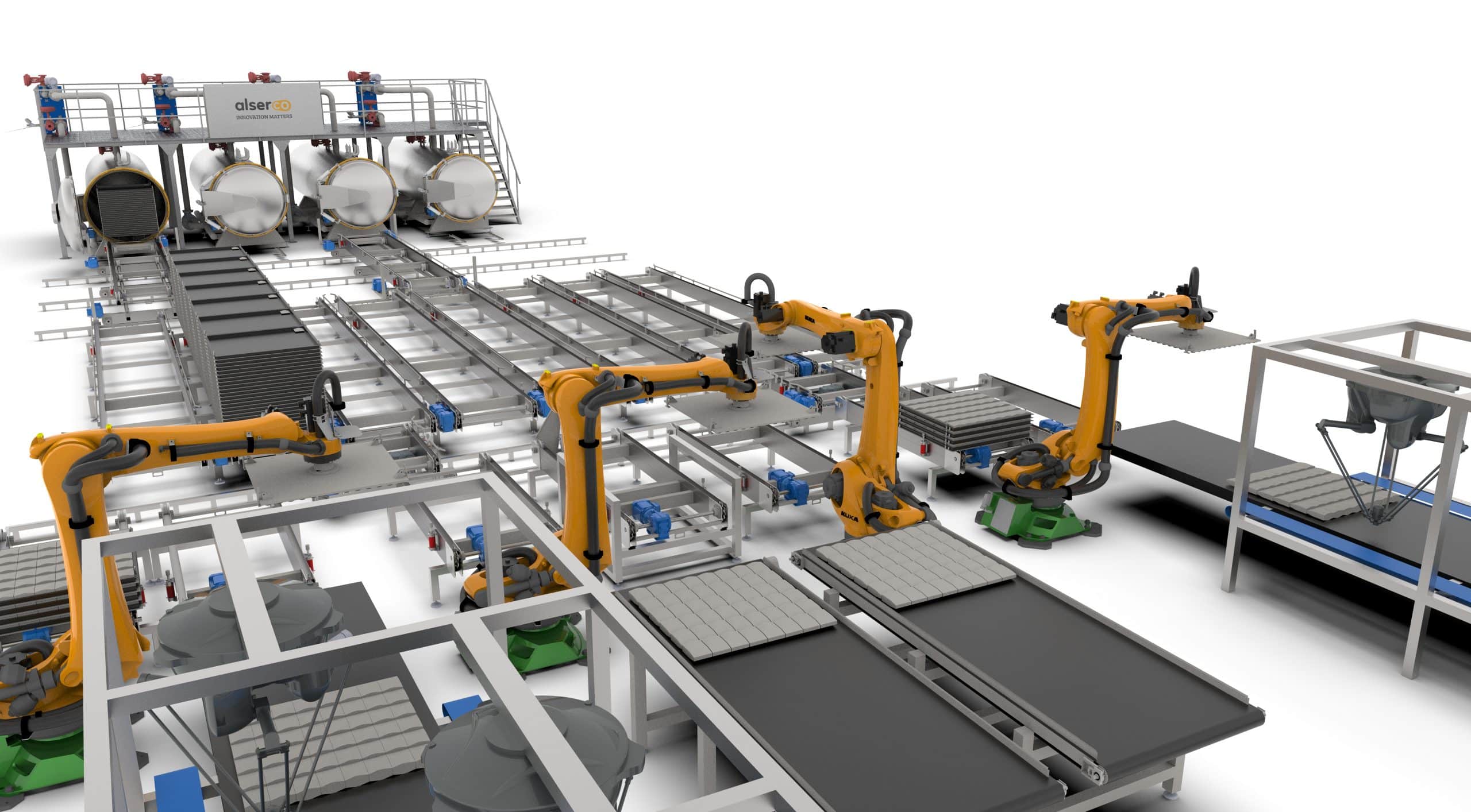

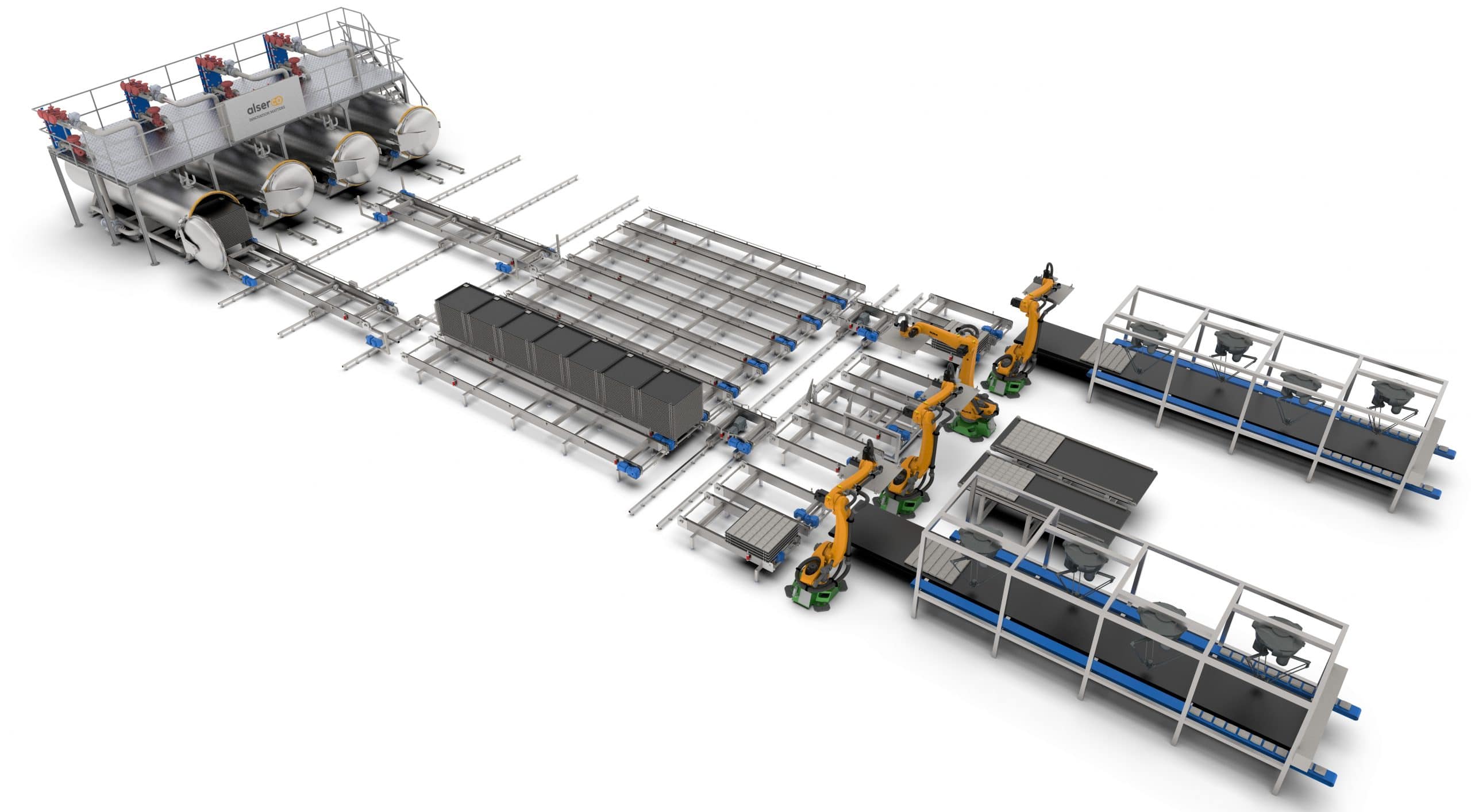

We automate the entire loading and unloading operations of your retorts, cookers or pasteurisers, digitalising the control of critical points through our own software.

Palletising and depalletising both rigid containers (cans, glass jars or plastic containers) and flexible containers (tetra, pouches and doypacks, among others).

Storage system for empty/full trolleys.

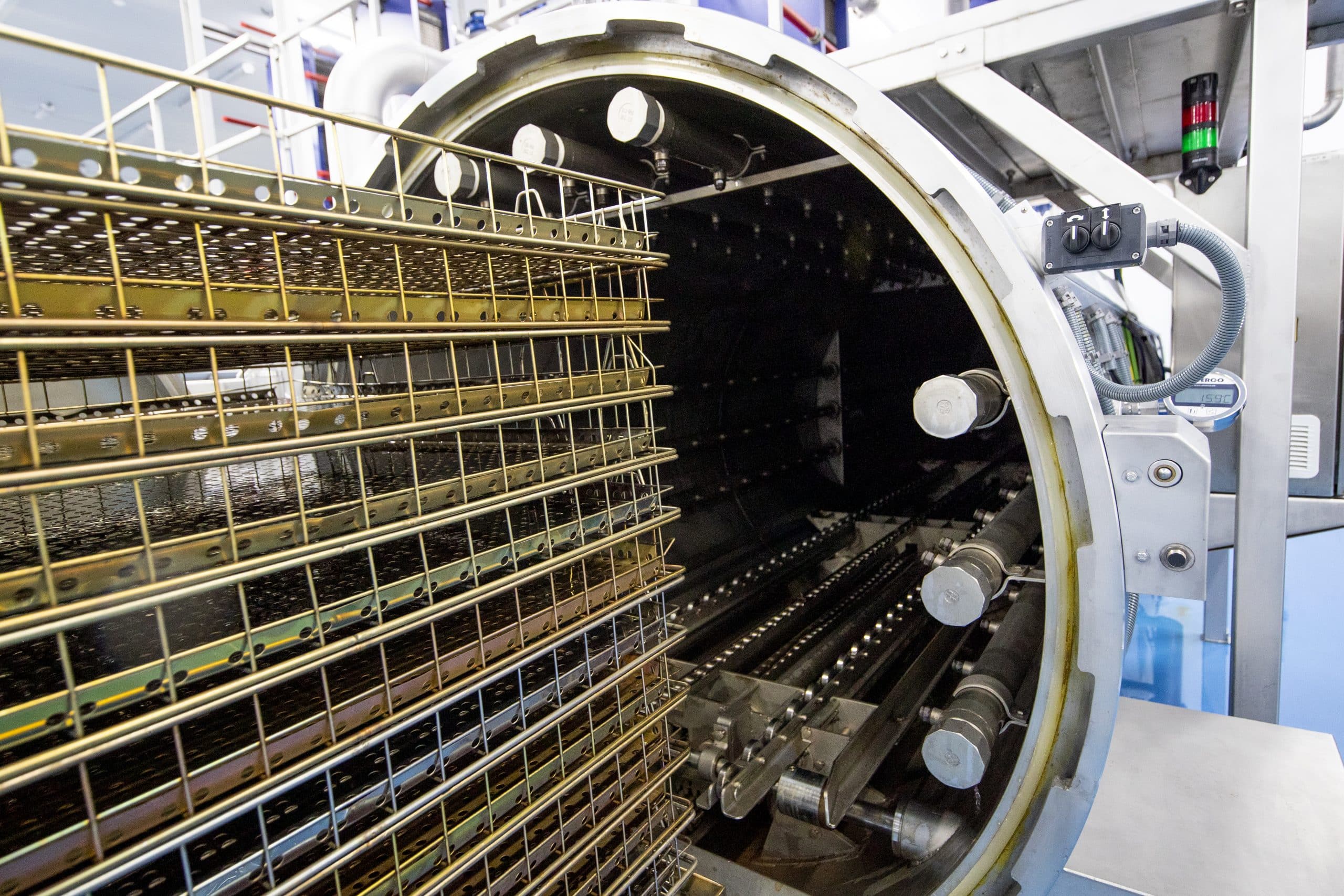

Loading and unloading of autoclave baskets.

monitoring and traceability

The entire process is monitored by a software that allows the traceability of the products in terms of its trajectory and other specific variables of the heat treatment.

MOTORIZED CIRCUIT AND AUTOMATIC TRANSPORTS

Alserco automatic loading systems to retorts or pasteurisers have a motorized circuit for the movement and accumulation of the baskets, as well as automatic transports to transfer the separators from the palletizer to the depalletizer.

Palletisers designed for the basketing and/or unbasking of all types of containers.

We have extensive experience in design and manufacture of trolleys and baskets for retorts, cookers and other similar equipment, as well as in the supply of separators made according to custom-made plans.

From Alserco, we place at your disposal all our “know-how” in the area of food heat treatment. We offer a comprehensive service that goes from the design and manufacturing of food processing machinery to training and consulting in food safety; all going through the process validation (temperature distribution and heat penetration: TD & HP studies).